Product description

- An industrial trowelable 2-component epoxy mortar.

- 3 times stronger than concrete.

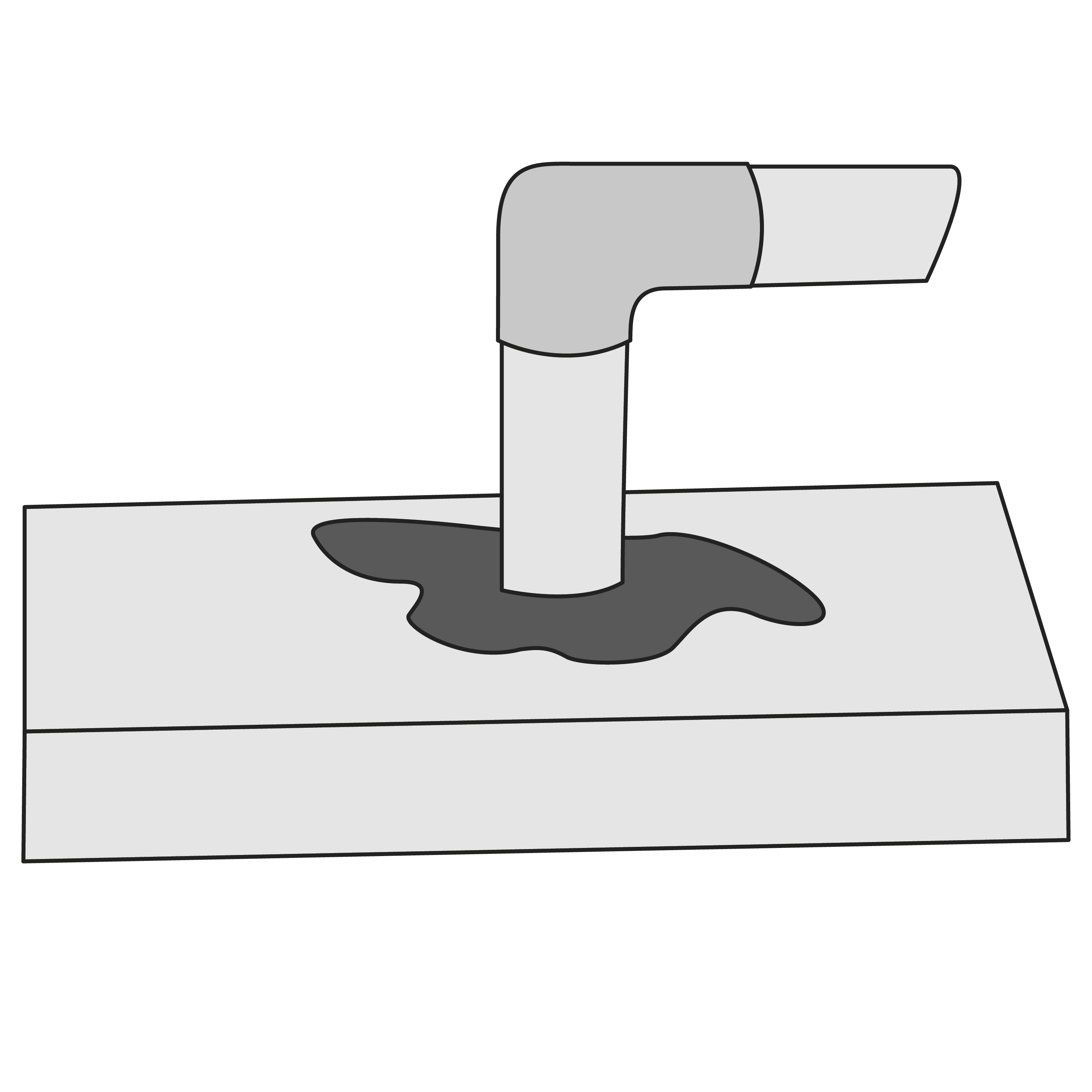

- Can be processed without extra primer or first coats.

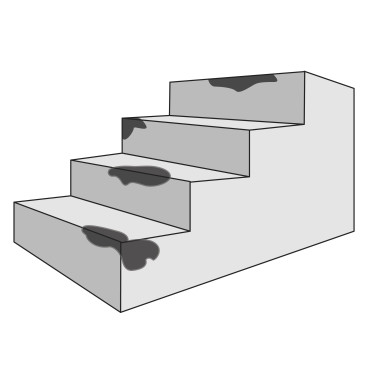

- Suitable for indoor and outdoor applications.

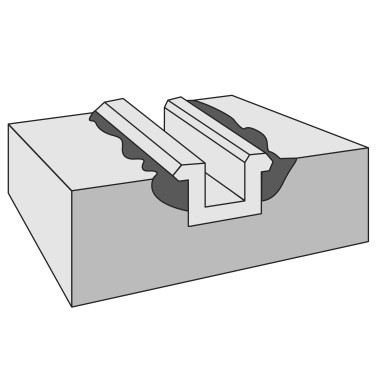

- Applicable in unlimited thicknesses and can be worked out to zero level without loss of strength and shrinkage.

- Stands up to heavy traffic, forklifts, pallet jacks.