Why finish with a straight edge at a 45° angle.

Primarily for horizontal joints. With a semi-circular finish (with the finger), you get a flat section at the bottom that runs very thin on the surface. Water can remain on there, which is an ideal microclimate for mould and bacteria. With a 45-degree finish, water drains away much easier and the joint dries faster, with less chance of mould growth. So always straighten horizontal joints in wet areas at 45 degrees.

The straight finish also has an advantage in joints exposed to sunlight. Because the thinner the layer, the more susceptible to being damaged by UV radiation. This is often the first visible damage to glass joints on windows, for example. With a straight finished joint, there is much less risk of UV damage thanks to the even thickness build-up.

Sometimes a rounded joint can be an aesthetic choice, but best only indoors, vertical and in dry areas. Use a Perfect Finish tool with rounded corners for this purpose.

- Select the appropriate Perfect Finish tool, moisten it and the fresh sealant with Prepare&Finish and smoothen the joint.

- Remove excess sealant.

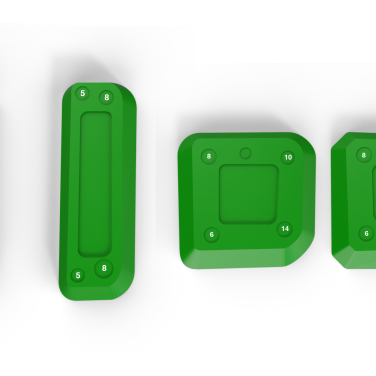

Elongated tool right angles 45°: 5 -8 mm

Elongated tool round corners radius: 5-8 mm

Round angles radius: 6-8-10-14 mm

Straight corners 45° : 6-8-10-14 mm