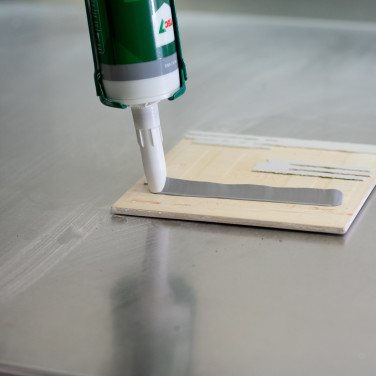

EC1 Plus

EC1 Plus EMICODE is an eco-label and classification system that certifies flooring installation products, adhesives, and building materials based on their emissions. It follows standards like DIN EN ISO 16000-1, CEN/TS 16516, and ISO/TC 146 on air quality. Products bearing the EMICODE label are certified as having very low emissions, adhering to the strictest limits, and are continuously monitored by independent inspection bodies. This ensures clean indoor air and promotes a healthy environment.